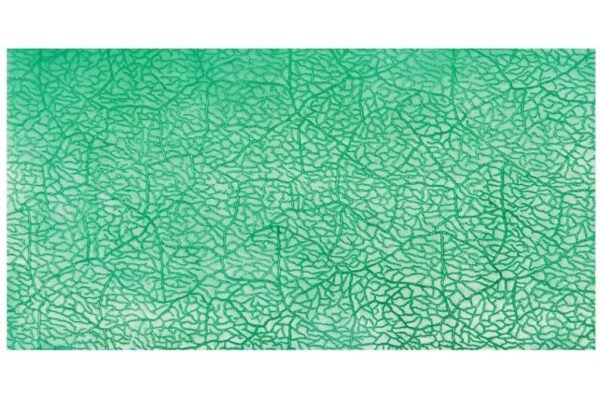

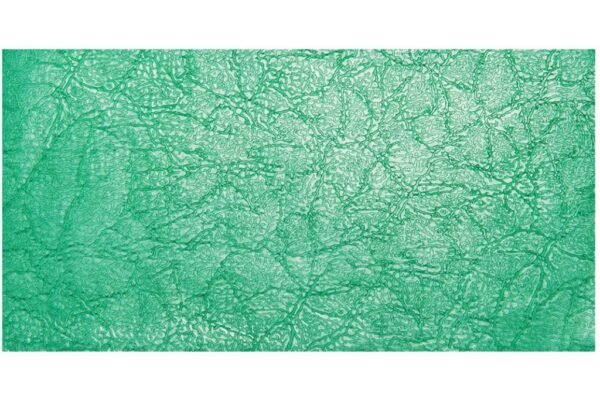

Casting wax is a type of modeling wax that is used for creating patterns or models for casting metal objects. It is a soft, pliable material that can be easily carved, shaped, and sculpted using a variety of tools. It is typically used in the lost wax casting process, in which the wax model is used to create a mold, which is then used to cast the final metal object. The wax model is melted or “lost” during the casting process, leaving behind a hollow space in the mold that is filled with molten metal. Casting wax is available in a range of colors, including white, yellow, and red, and can be used to create a wide variety of objects, including jewelry, sculptures, and architectural elements.

The process typically involves the following steps:

- Creating a wax model: The desired object is sculpted or shaped using casting wax, which is a soft, pliable material that can be easily carved, molded, and shaped using a variety of tools.

- Creating a mold: The wax model is then used to create a mold, which is typically made of a refractory material such as plaster, investment, or ceramic. The mold is made by coating the wax model with a layer of refractory material and allowing it to harden.

- Melting the wax inlay casting wax: The mold is then heated to a high temperature, melting the wax and leaving behind a hollow space in the shape of the desired object.

- Pouring the metal: Molten metal is then poured into the hollow space in the mold, filling it to create the final metal object.

house of wax 2005 cast is available in a range of colors, including white, yellow, and red, and can be used to create a wide variety of objects, including jewelry, sculptures, and architectural elements. It is a popular choice for artists and craftspeople because it is easy to work with and can be molded into intricate shapes and details.

Reviews

There are no reviews yet.