In the world of dental restorations, achieving high accuracy, ease of use, and superior durability is crucial. Wax Discs, an essential tool for dental labs and professionals, offer these qualities and more. Engineered to support complex restorations and intricate details, these discs serve as an ideal material for casting and creating dental prosthetics. In this article, we’ll explore the benefits, applications, and specifications that make high-quality wax discs a top choice for dental professionals.

What are Wax Discs?

Wax Discs are specialized dental materials designed for precise and clean casting in various types of dental restoration work. These discs are often used in CAD/CAM systems for creating crowns, bridges, and other dental appliances. Known for their easy handling, clean burn-out, and high stability, wax discs support dental technicians in achieving smooth finishes and high precision in restorations.

2. Key Benefits of Using Wax Discs

2.1 Precision and Accuracy

Wax discs allow for meticulous detailing, crucial for restorations that demand high accuracy. Their composition enables dental technicians to create clean, sharp details and smooth surfaces in molds, ensuring a snug fit and natural look.

2.2 Ease of Use

These discs are crafted to be user-friendly and easy to handle. They carve smoothly, enabling technicians to efficiently shape and refine restorations. Their formulation allows seamless integration with CAD/CAM technology, simplifying complex procedures and saving valuable time.

2.3 Consistent Quality

High-quality wax discs offer consistent results across multiple uses, making them a reliable choice for dental labs. Their stability during milling or casting helps in achieving uniform results, which is essential for maintaining high standards in dental restorations.

3. Specifications of Wax Discs

Wax discs come with unique specifications designed to meet the needs of various restoration processes. Here are some standard specifications that define their quality and usability:

- Material Composition: High-grade wax with a low melting point for a clean burn-out.

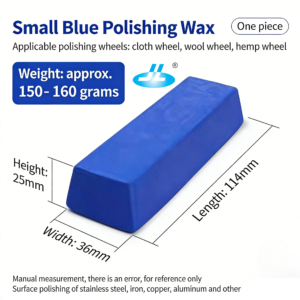

- Thickness Options: Available in multiple thicknesses, typically ranging from 10mm to 25mm, to suit various applications.

- Color Options: Often available in shades like blue, green, or white for easy visibility and differentiation in the lab.

- CAD/CAM Compatibility: Designed to work seamlessly with most milling machines for efficient and precise processing.

- Thermal Stability: Engineered to withstand milling without distortion, ensuring smooth handling during both carving and burn-out.

4. Applications in Dental Restorations

Wax discs are primarily used in crafting:

- Crowns and Bridges: Ensuring a precise fit and natural appearance for patients.

- Full and Partial Dentures: Ideal for forming the framework and detailing needed in dentures.

- Implants and Inlays: Offering the precision required for complex dental implants and inlays.

- Dental Models and Prototypes: Wax discs are commonly used for creating accurate models to help dentists visualize and plan treatments.

5. Why Choose High-Quality Wax Discs?

The investment in premium-quality wax discs pays off in efficiency, reliability, and end-results. High-quality wax reduces the risk of errors, minimizes wastage, and helps dental technicians achieve the best possible outcomes in restorative work. Choosing top-grade materials like wax discs ultimately enhances patient satisfaction by delivering restorations that are both comfortable and long-lasting.

6. Conclusion

Advanced wax discs play an indispensable role in modern dental restorations, offering unparalleled accuracy and ease of use in demanding applications. Their compatibility with CAD/CAM systems and user-friendly design make them a go-to choice for dental labs aiming for excellence. By investing in high-quality wax discs, dental professionals can elevate their craftsmanship, delivering exceptional results that enhance patient comfort and satisfaction.

FAQ: Wax Discs in Dental Restorations:

1. What are Wax Discs used for in dental labs?

Wax Discs are primarily used in dental labs to create precise molds for dental restorations, including crowns, bridges, dentures, and implants. They support the casting process and are often compatible with CAD/CAM systems, enabling accurate and efficient restorations.

2. How do Wax Discs contribute to precision in dental restorations?

Wax Discs are formulated to provide smooth carving and fine detailing, allowing technicians to achieve exact fits and natural-looking results. Their stability during milling and casting ensures accuracy, which is essential for high-quality restorations.

3. Are Wax Discs compatible with CAD/CAM technology?

Yes, high-quality Wax Discs are designed to work seamlessly with most CAD/CAM milling systems, making them ideal for creating precise molds in a variety of dental restoration processes. Their easy handling and compatibility streamline the restoration process.

4. What specifications should I look for in a high-quality Wax Disc?

Key specifications include material composition (for a clean burn-out), thickness options (typically 10mm to 25mm), color choices for lab visibility, CAD/CAM compatibility, and thermal stability to maintain form during carving and casting.

5. Do Wax Discs come in different thicknesses?

Yes, Wax Discs are available in various thicknesses, usually ranging from 10mm to 25mm, to suit different restoration needs. The right thickness depends on the type of dental appliance being crafted, such as crowns, bridges, or full dentures.

6. What colors are available for Wax Discs, and does color matter?

Wax Discs commonly come in shades like blue, green, or white. The color is mainly for easy visibility and distinction in the lab, helping technicians differentiate between types and thicknesses, but it doesn’t impact the performance of the wax.

7. Can Wax Discs withstand high temperatures during casting?

Yes, Wax Discs are engineered for thermal stability. They maintain their structure during milling and burn out cleanly in high temperatures, ensuring no residue is left that could affect the final cast.

8. Why should I invest in premium-quality Wax Discs?

High-quality Wax Discs offer consistent results, reduce the chance of errors, and enhance precision in dental restorations. By choosing reliable discs, you ensure smoother processes, less waste, and a better fit for patient comfort and satisfaction.

9. Are Wax Discs suitable for all types of dental restorations?

Wax Discs are versatile and ideal for many restorations, including crowns, bridges, inlays, dentures, and implants. Their flexibility and precision make them a valuable asset in any dental lab looking to achieve high-quality results across various applications.

10. How do Wax Discs improve the patient experience?

Using high-quality Wax Discs ensures restorations are crafted with precision, which leads to a comfortable fit and natural appearance. This ultimately increases patient satisfaction with their dental restorations, leading to a positive experience with their dental care.