Wax patterns are used in the process of casting metal parts. They are typically made of wax or another material that can be easily shaped and is suitable for making a mold. The wax pattern is used to create a mold, which is then used to cast the metal part.

- Design: The first step is to create a design for the wax pattern. This can be done using computer-aided design (CAD) software or by hand.

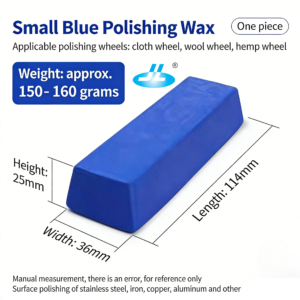

- Modeling: The design is then used to create a physical model of the wax pattern, typically using a 3D printer or by hand carving the pattern from a block of wax.

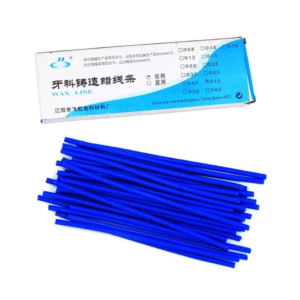

- Spring and gating: Once the wax pattern is complete, it is attached to a “tree” of wax rods (called sprues) and gates, which will eventually be used to pour the molten metal into the mold.

- Mold making: The wax pattern is then used to create a mold, which is typically made of plaster or another material that can harden around the wax pattern.

- Casting: Once the mold is complete, it is heated to melt the wax out of the mold (a process called “investment”). The molten metal is then poured into the mold and allowed to cool, resulting in a cast metal part.

The design for the wax pattern can be created using CAD software, which allows the designer to create a 3D model of the desired part. The design can also be created by hand, using a sketch or physical model as a reference. wax patterns, wax pattern making, jewelry wax patterns, wax casting, lost wax casting, wax patterns design

Wax patterns are commonly used in the jewelry-making and dental industries, as well as in the production of small metal parts for a variety of applications.

Reviews

There are no reviews yet.