Casting wax explanation

Casting wax is a type of modeling wax that is used for creating patterns or models for casting metal objects. It is a soft, pliable material that can be easily carved, shaped, and sculpted using a variety of tools. It is typically used in the lost wax casting process, in which the wax model is used to create a mold, which is then used to cast the final metal object. The wax model is melted or “lost” during the casting process, leaving behind a hollow space in the mold that is filled with molten metal. Casting wax is available in a range of colors, including white, yellow, and red, and can be used to create a wide variety of objects, including jewelry, sculptures, and architectural elements.

Casting wax uses

Casting wax is a type of material that is used in the lost wax casting process, which is a method of casting metal objects by creating a mold from a wax model. The process typically involves the following steps:

- Creating a wax model: The desired object is sculpted or shaped using casting wax, which is a soft, pliable material that can be easily carved, molded, and shaped using a variety of tools.

- Creating a mold: The wax model is then used to create a mold, which is typically made of a refractory material such as plaster, investment, or ceramic. The mold is made by coating the wax model with a layer of refractory material and allowing it to harden.

- Melting the wax: The mold is then heated to a high temperature, melting the wax and leaving behind a hollow space in the shape of the desired object.

- Pouring the metal: Molten metal is then poured into the hollow space in the mold, filling it to create the final metal object.

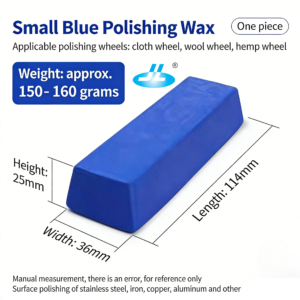

specification of dental casting wax

Casting wax is available in a range of colors, including white, yellow, and red, and can be used to create a wide variety of objects, including jewelry, sculptures, and architectural elements. It is a popular choice for artists and craftspeople because it is easy to work with and can be molded into intricate shapes and details.

Classification of casting wax

There are several different types of casting wax that is used for different purposes. Here are a few common types:

- Spring wax: This is a thin, flexible wax that is used to create channels, or “sprues,” through which the molten metal will flow during the casting process.

- Chasing wax: This is a harder, more durable wax that is used to add details and finishing touches to a wax model.

- Injection wax: This is a very soft, pliable wax that is used in the injection wax casting process, in which the wax is injected into a mold to create a copy of the original model.

- Investment wax: This is a type of casting wax that is used to create molds for casting metal objects. It is mixed with water and a refractory material to create a slurry, which is poured over the wax model and allowed to harden.

- Modeling wax: This is a soft, pliable wax that is used for creating models and prototypes. It is often used in the automotive and aerospace industries to create mockups of parts and components.

- Pattern wax: This is a hard, durable wax that is used to create patterns for casting metal objects. It is often used in the manufacturing industry to create patterns for mass production.

How to use casting wax in the dental lab

In a dental lab, casting wax is often used to create models of teeth and other dental structures. Here are the general steps for using casting wax in a dental lab:

- Prepare the wax: Before using the wax, it may need to be softened by heating it slightly. This can be done using a wax pot or by heating it in a microwave for a few seconds. The wax should be soft enough to be easily shaped, but not so soft that it becomes too sticky to work with.

- Shape the wax: Once the wax is prepared, it can be shaped and sculpted using a variety of tools, such as carving knives, spatulas, and sculpting instruments. The wax can be molded and shaped to create a model of the desired dental structure, such as a tooth or bridge.

- Create the mold: Once the wax model is complete, a mold can be created using a refractory material such as plaster, investment, or ceramic. The mold is made by coating the wax model with the refractory material and allowing it to harden.

- Melt the wax: The mold is then heated to a high temperature, melting the wax and leaving behind a hollow space in the shape of the desired dental structure.

- Pour the metal: Molten metal is then poured into the hollow space in the mold, filling it to create the final dental restoration.

Casting wax is an important tool in a dental lab, as it allows dental technicians to create accurate, detailed models of teeth and other dental structures for use in the fabrication of dental restorations such as crowns, bridges, and implants.