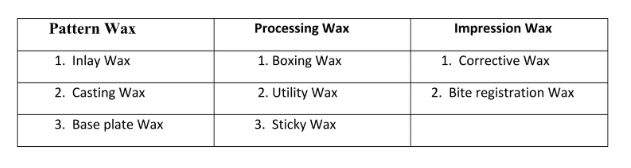

Dental Waxes

Pattern Waxes

• Used to form general pre-determined size & contour of an artificial restoration,

• Later it is replaced by more durable material such as cast gold, cobalt-chrome nickel alloys, etc.

• They exhibit a thermal change in dimension and warpage on standing.

INLAY WAXES

• Inlays, crowns & bridge units are formed by a casting process that uses a lost wax pattern technique.

• A pattern of wax is constructed that duplicates the shape and contour of the casting.

• After investing & spring the wax is eliminated by heating.

Typical Composition

Paraffin- 60%

Carnauba- 25,

Ceresin- 10%

Casting wax

These come in sheets and preformed shapes.

The physical properties are similar to inlay wax except for the melting range.

The melting range is only important for laboratory

Functions

⚫ Used to produce the metallic component of the partial denture on the cast.

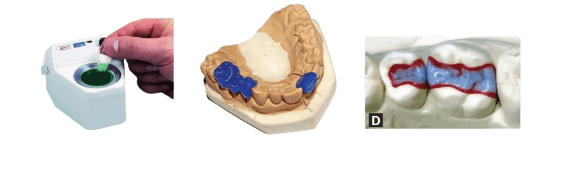

Milling Wax

Inlay wax

A. Two forms of inlay waxes. B. Wax bath used for dipping technique. C. Wax patterns of crowns made from inlay wax. D. Inlay pattern(JLwax,2022)

Functions

⚫ It is used to make patterns for metallic restorations.

⚫ Patterns for inlays,

⚫ crowns, and bridges are first made in wax and then converted into metal or ceramic by casting.

PROCESSING WAXES

Used primarily as auxiliary aids in constructing a variety of restorations and appliances.

Sticky wax

. It is sticky when melted, with a max 5 %flow at 30 C° and 90% at 43 C° and adheres closely to the surfaces when applied to it.

. If movement occurs the wax tends to fracture than distort.

. At room temperature, the wax is firm, free from tackiness, and brittle.

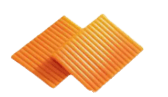

IMPRESSION WAXES

Impression waxes, though rarely used to record complete impressions, can be effectively used to correct small imperfections in other impressions.