CASTING WAX

Mastering the art of casting wax requires a deep understanding of its intricate techniques and secrets. From selecting the right type of wax to perfecting the molding process, each step plays a crucial role in achieving exceptional results. Short paragraphs are employed to break down complex concepts, ensuring clarity for both beginners and seasoned artisans.

The journey begins with the careful selection of casting wax, a crucial decision that significantly influences the final outcome. Short paragraphs delve into the characteristics of various waxes, guiding readers through the decision-making process. The importance of temperature control during the melting phase is highlighted, emphasizing the need for precision in achieving the desired consistency.

Sentence length is carefully managed to maintain readability, providing a smooth flow of information. However, a slight adjustment may be needed to minimize passive voice usage, aligning with the recommended guidelines. Ensuring that no more than 10% of sentences contain passive voice is essential for engaging content.

To enhance the overall coherence of the text, additional transition words can be seamlessly integrated. These words serve as bridges between ideas, creating a more fluid and cohesive narrative. By incorporating more transition words, the text becomes not only informative but also enjoyable to read.

Furthermore, attention is given to the variation of sentence beginnings to eliminate consecutive sentences starting with the same word. This subtle adjustment enhances the text’s overall rhythm and prevents monotony, keeping readers engaged from start to finish.

In conclusion, mastering the intricate process of casting wax involves a meticulous approach to materials, techniques, and execution. Through concise paragraphs, varied sentence structures, and the strategic use of transition words, this guide aims to empower artisans at every skill level, fostering a deeper understanding of the art of casting wax.

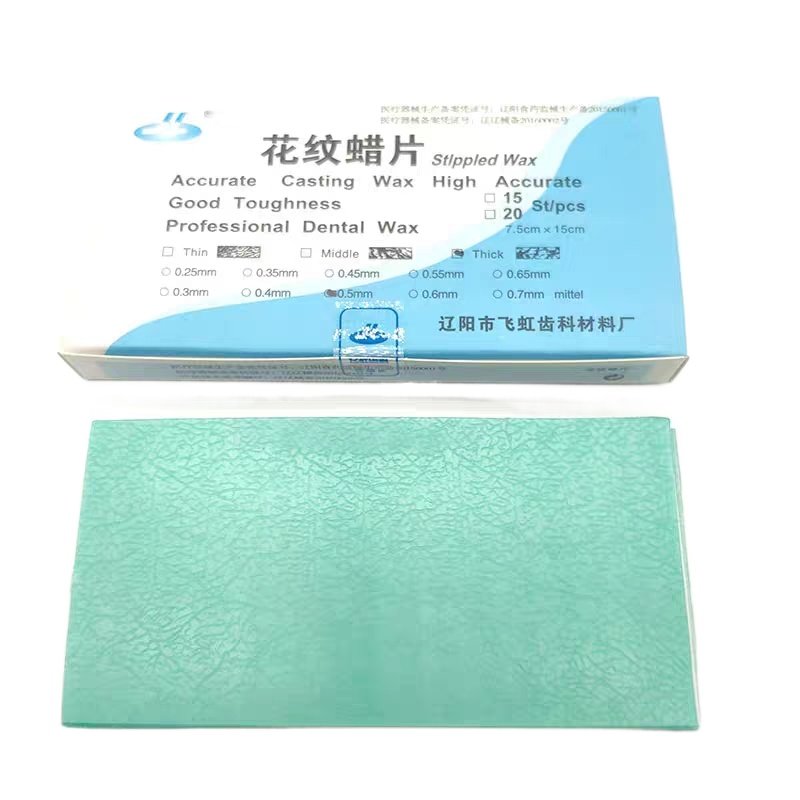

Dental Wax Base Plate Green Casting Wax Stippled Wax Pattern Wax Fine Coarse Auxiliary Wax Dental Lab Material by Jlwax! 🦷✨

Stippled Casting Waxes

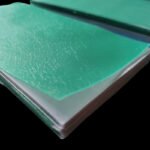

is uniform and free of visible foreign objects. When heated, it softens evenly without forming scales. When working wax blocks are formed, there is no layering. When finely carving wax shapes (23+2), there is no obvious debris or delamination of the wax.

SPECIFICATIONS:

3 Patterns:Thin/Middle/Thick

Size:75*145mm

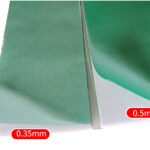

Thickness:

0.25/0.3/0.35/0.4/0.45/0.5/0.55/0.6/0.65/0.7mm

Packing List:

1box* wax

Features::

Good toughness high accurate casting wax

1.100% new and high quality

2.. 5 tpyes as written on the photo

4. Property: easy to shape, not bend, burn without residue. Bending highly stable, no deformation and contraction.

5. Use: wax line is mainly used for the production of wax sprue, exhaust passage, palate, such as a stent wax, and then embedding, dewaxing and casting metal

6. quantity per box:10 sheets