Wax wire is a type of wax that is shaped into a thin, flexible wire form. It is commonly used in the casting process as a material for creating sprues, which are small channels that connect the casting mold to the main body of the casting. The wax wire is melted and poured into the sprues to create a temporary channel for the molten metal to flow through during the casting process. After the casting is complete, the wax is melted out, leaving behind a porous structure in the casting that can be filled with metal or other materials to strengthen the casting.

Advantages

- Dimensionally stable patterns.

- Stress-free working.

- Easily adaptable.

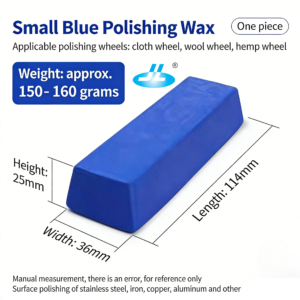

Proper tackiness and adhesion extruded to a uniformed diameter of 1/2 lb With Sizes 2.0, 2.5, 3.0, 3.5, 4.0, and 5.0Round Spool

In the casting process, wax wire is used to create a pattern of the desired casting shape. This pattern is then used to create a mold, which is typically made of a material such as plaster or sand. The mold is used to shape the molten metal into the desired shape as it cools and solidifies.

To create the sprues, the wax wire is melted and poured into the mold, forming small channels that connect the main body of the casting to the surface of the mold. These channels allow the molten metal to flow into the mold and take on the shape of the casting as it cools.

After the casting is complete, the wax is melted out of the mold, leaving behind a porous structure in the casting. This structure can then be filled with metal or other materials to strengthen the casting and improve its structural integrity.

Wax wire is a useful material for creating sprues because it is easily melted and poured, and it leaves behind a porous structure that can be easily filled in during the casting process.

Reviews

There are no reviews yet.